|

|

IMG_3327em

Next request was for a compression check. 80/80, 80/80, 80/80, 79/80. No problem there. But while doing this I decided to check the plugs. Cylinder #3 plugs looked different. WHY?

Date: 06/12/2012

Views: 6610

|

|

|

IMG_3331em

Turn the plugs over and one plug on #3 looks funny. Calls for a closer look...

Date: 06/12/2012

Views: 5629

|

|

|

IMG_3332em

Looks like that plug had been bumped some time during transport. Porcelain shows a crack. OK, replaced ALL the plugs. Engine still didn't run right.

Date: 06/12/2012

Views: 7334

|

|

|

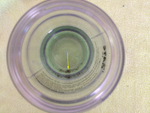

IMG_3334post

Requests to check the fuel delivery system. Started with the gascolator. Any large quantity of crap in the gascolator? Here's the fuel from the gascolator in the test vessel. A tiny bit of black crud from who knows what. But not enough to cause a pro

Date: 06/13/2012

Views: 5906

|

|

|

IMG_3367post

Request for fuel pressure input to the fuel pressure regulator. Installed a fuel pressure sensor on the input to the regulator. So now we have differential pressure out of the regulator and pressure into the regulator.

Date: 07/02/2012

Views: 5704

|

|

|

IMG_3374em

Run the engine, check the pressures. All seems OK. 5 lbs into the regulator and 3.8 lbs out of the regulator. This is with the Billet mechanical pump. Which became the next source of concern.

Date: 07/04/2012

Views: 5487

|

|

|

IMG_3384em

Remove the Billet pump from the circuit. Run with only electric pump. Input line connected directly to the regulator. At the same time, remove airbox pressure from differential gauge to get absolute fuel pressure out of regulator.

Date: 07/09/2012

Views: 6457

|

|

|

IMG_3392

Differential pressure with engine running on electric pump: 3.8 lbs

Date: 07/09/2012

Views: 6125

|

|

|

IMG_3391em

Input fuel pressure: 5 lbs. Just like with the Billet pump. Next request was for a fuel flow test. Reconnected the Billet pump to the fuel circult. One electric pump running fuel through the billet pump produced 1 gallon of fuel in a bit less than 3 m

Date: 07/09/2012

Views: 8723

|

|

|

IMG_3438em

There was a bit more work with the Billet pump package, but it proved not to be the problem. Moving on, OK, not the fuel system. Try running the engine as a normally aspirated engine. Remove the connection between the turbo and airbox. Believe it or

Date: 07/17/2012

Views: 8856

|