|

|

New MC-4A01

2012 04 12 - Well, didn't take very long today to decide the new brake assembly wouldn't fit. It's too long.

Date: 04/11/2012

Views: 4654

|

|

|

New MC-4A02

And it's too wide to fit in between the mounts. I have 1 1/4 x 1 1/4 x 1/8 Al angle on order to fix the width problem and I think I know how to fix the length problem as well. Then I can address the height issue...

Date: 04/11/2012

Views: 4437

|

|

|

New MC-4A 03

2012004 15 - In order to get the new MC-4A's to fit within the available space, the threaded end has to be shortened so that when the attach fitting is screwed on fully, there will be not threaded end protruding into the attach fitting. Removing this muc

Date: 04/12/2012

Views: 4941

|

|

|

New MC-4A 04

The MC-4A's must fit within this length and that 3/4" should allow the fit.

Date: 04/15/2012

Views: 4848

|

|

|

New MC-4A 05

With the attach fitting fully screwed on to the end of the thread, the last bit of thread is just visible in the fitting.

Date: 04/12/2012

Views: 4200

|

|

|

New MC-4A 06

Now the aft ends of the MC-4A's will be within the limits while the brake levers are properly positioned for operation and fit.

Date: 04/12/2012

Views: 4308

|

|

|

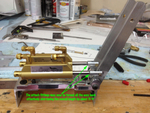

New MC-4A 07

Now we need mounting brackets. 1 1/4x1 1/4x1/8 aluminum angle has been cut to length (5 1/4 in) and is positioned on the brake mount for drilling the mounting holes using a wood block and clamp.

Date: 04/14/2012

Views: 4647

|

|

|

New MC-4A 08

With the mounting holes drilled and the sides cut away the brackets are attached to the mount.

Date: 04/15/2012

Views: 4382

|

|

|

New MC-4A 09

The MC-4A's with brake levers are assembled and positioned to allow the location for the aft holes to be established.

Date: 04/15/2012

Views: 5151

|

|

|

New MC-4A 10

The aft holes have been drilled and the MC-4A's are bolted in place to check the fit.

Date: 04/15/2012

Views: 4358

|